Chennai11 hours ago

- Copy link

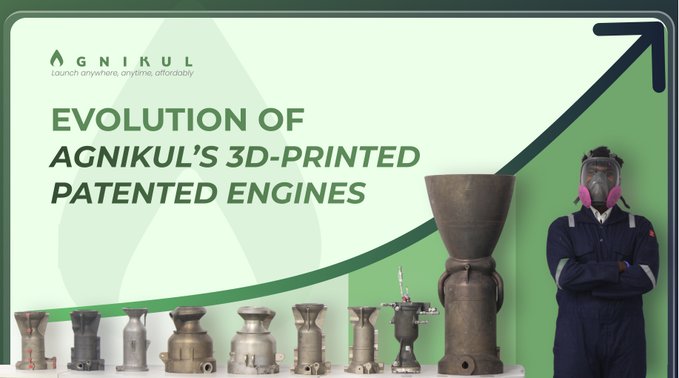

Now astronauts will be able to move into space with a rocket with a med-in-India engine. Indian Space Tech Startup Agnikul Cosmos has created the world’s largest single-piece 3D printed rocket engine. The special thing is that this engine is not made by connecting the parts, but it is completely prepared in one part.

That is, neither welding nor any joints or bolts have been installed in making it. The Space Startup in Chennai has prepared it with 3D printing technology at once and has taken it just 72 hours to make it. Not only this, the company has also got a patent for its design and manufacturing in the US.

Rocket launching from engine will be safe

Agnikul Cosmos is made from a special metal called the engine called Inconel, which is strong and anti -corrosion for space travel. Its specialty is that due to the formation in the same piece, there are less chances of failing it, which makes the rocket launch more safe.

This design makes the engine much stronger, lighter and much easier in production. Agnikul says that this may reduce production time by more than 60% and can also reduce the possibility of technical fault.

Manufacturing at IIT Madras Research Park

This engine will be used in Agnikul’s ‘Agniban’ rocket, which can carry a payload of up to 300 kg to a height of 700 km. To make this engine, Agnikul’s manufacturing plant is at IIT Madras Research Park, which is India’s first 3D printed rocket engine factory.

It was started in 2022 by Tata Sons chairman N Chandrasekaran and ISRO Chief S Somnath. Also, with the help of ISRO and In-Space, Agnikul has got support for testing and launching.

Launching journey

- Agnikul was started in 2017 by some graduates of IIT Madras-Srinath Ravichandran, Moin SPM and Professor SR Chakraborty. He incubated it at the National Center for Combaston Research and Development.

- Initially, this startup, which started with a seed funding of Rs 3 crore, has so far raised $ 40 million (about Rs 335 crore).

- In 2023, a series B funding of $ 26.7 million (about Rs 234 crore) gave it further strength. It fired the first test of its ‘Agnilate’ engine in 2021, which was single-piece 3D printed.

- On 30 May 2024, Agnikul launched ‘Agniban Sorted’ (Sub-Arbitatic Technology Demonstrator) from his private launchpad ‘Dhanush’. It was the first private launchpad in India, which was built in Sriharikota.

- The mission scored 3 large milestones-first private launch, first semi-crossing engine and world’s first single-piece 3D printed engine.

- However, the first 4 attams failed, but the fifth succeeded. The rocket flew to an altitude of 8 km and made landing in the Bay of Bengal.

Future planning

The purpose of Agnikul is to bring space cheaper and access. This startup will give customized launch solutions for payloads ranging from 30 kg to 300 kg. There are plans to start regular flights by 2025, and India may play a big role in making Space Superpower in the coming years.

Ravichandran said- this result of our 1000 hours of hard work

ISRO Chief Dr. S Somnath described it as an example of ‘Indigenous Innovation’, while In-Space Chairman Dr. Pawan Goenka said that this is a big step for private space industry. Agnikul co-founder Srinath Ravichandran said, ‘This is the result of our 1000 hours of hard work. Now we are preparing for the Orbital Mission by the end of 2025. People on posts and web are calling it a revolution in India’s space technology.